Performance and use

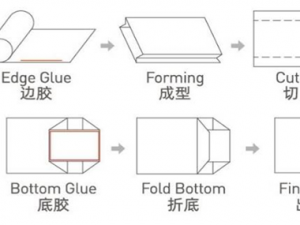

This Kraft Paper Bag Making Machine is used for roll primary color paper or printed roll paper such as kraft paper. Paper rolls such as food paper are completed by this machine at one time. Automatic center gluing, raw material into tube, cut to length, bottom indentation, bottom folding. Glue on the bottom and form the bottom of the bag. Finished bag etc.all is completed at one automatic process. This take away paper bag making machine is more convenient to operate, more efficient and more stable. It is an environmentally friendly paper bag machine equipment that produces various paper bags, snack food bags, bread bags, dried fruit bags, etc.It also can be made as full automatic paper handle bag making machine, if we add the paper handle making machine inline.

Main feature:

- Using touch screen man-machine interface,the operation function is clear, easy to control

- Adopt the Japan original Mitsubishi controller,operation stability

- Japan Mitsubishi servo motor with German Sick photocell correction,accurate tracking.

- The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

- The raw material correction adopts servo motor to reduce the adjustment time of paper roll alignment.

0086-158-58563760

0086-158-58563760