The Honeycomb Paper-Making Machine: How It Works

Honeycomb paper-making machine consists of five parts: pulp preparation system, paper forming system, cloth mesh belt conveyor, drying system, and control system. In the pulp preparation system, the wood chips are first broken into small pieces and then screened to remove impurities.

The sieved wood chips are mixed with water to form a thick slurry, which is transported to the four-head box through a pipeline. The tank is a pressure vessel where the fibers in the slurry are divided into primary, secondary, and tertiary streams. The chest has baffles to prevent fibers from coalescing. A properly designed and operated box will provide uniformity of fiber quality in the final product.

Honeycomb paper machines enable the production of honeycomb paperboard. This type of cardboard is characterized by a large amount of air inside its hexagonal cells.

The manufacture of this board requires forming lines and molds specially designed for the production of honeycomb boards. In addition, the machine must be equipped with an airtight system to blow compressed air into the pulp and water mixture as it is being formed.

What is a honeycomb paper-making machine?

A honeycomb paper machine is a paper machine for making paperboard with a honeycomb structure. This paper is made from a variety of materials, including pulp, recycled paper, and even plastic.

Honeycomb paper machines are designed to make a sheet of paper with a series of hexagonal cells or pockets in it. The pockets are made from a series of metal sheets arranged in a honeycomb pattern. This type of paperboard is commonly used in packaging applications. A honeycomb paper machine usually consists of a web forming machine, a honeycomb machine, and a gluing machine.

The different parts of the machine

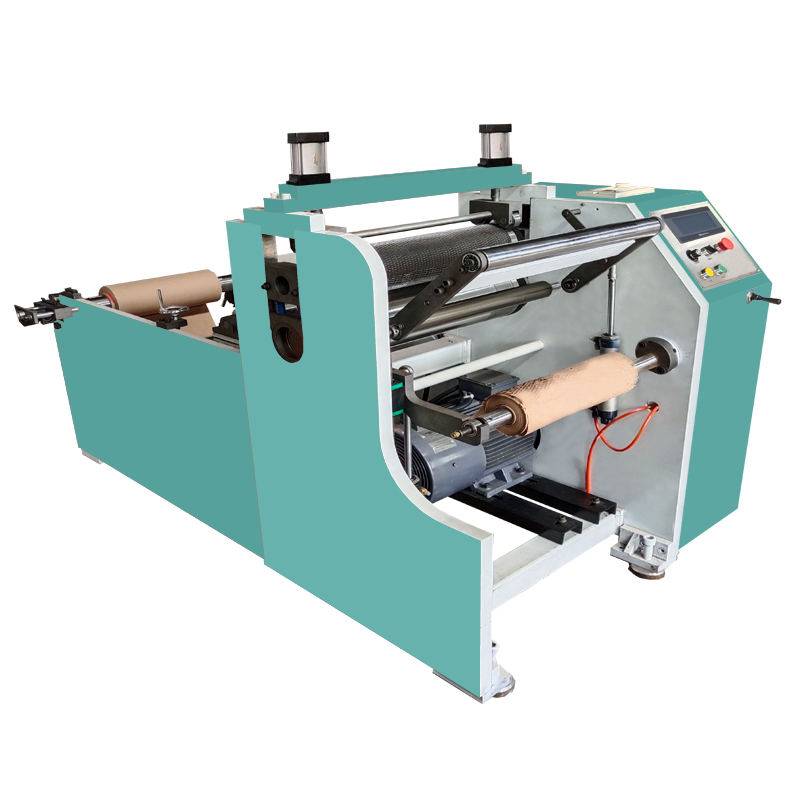

- Honeycomb paper machine consists of the following components:

- The frame is the main structure of the machine.

- The engine is the power of the machine.

- The transmission helps transfer power from the engine to the wheels.

- Wheels allow the machine to move.

- The braking system slows or stops the machine.

- The drivetrain transmits power from the engine to the wheels.

- The suspension system absorbs shocks and keeps the machine stable.

Body panels enclose and protect machine components.

How does the honeycomb paper-making machine work?

A honeycomb paper machine is a machine used to manufacture paper products such as cartons and paper cups. The machine is able to make these paper products by using a process called corrugation. This type of paper is made by bonding two layers of paper together with a honeycomb layer in between.

Honeycomb paper machines work by taking a sheet of paper and scoring it with a series of knives. These knives create small cuts in the paper that allow the paper to be bent and shaped into the desired product.

Once the paper is scored, it is fed into a series of rollers that complete the corrugating process. The layers are then put into the machine and bonded together with the honeycomb layer. Once the three layers are glued together, the honeycomb paper is then cut to the desired shape and size.

The benefits of using a honeycomb paper-making machine

A honeycomb paper machine is a machine for making paper honeycombs. These machines are highly efficient and can produce large quantities of paper honeycombs in a short period of time. Honeycomb paper machines have many advantages that make them ideal for a variety of industrial and commercial applications.

First, honeycomb paper machines are faster than conventional paper machines. This means that more products can be produced in less time, saving production costs.

Second, honeycomb paper machines consume less energy than traditional paper machines. This is because the honeycomb structure of the paper uses less water and pulp, making the production process more efficient.

Third, honeycomb paper is stronger and more durable than traditional paper. This makes it ideal for a wide range of applications, from packaging to construction.

To wrap things up

This article introduces the honeycomb paper machine and its working principle. Due to its unique design, the machine is capable of producing high-quality paper at high speed. If you are interested in learning more about honeycomb paper machines, please feel free to contact us. Our email is [email protected].

0086-158-58563760

0086-158-58563760